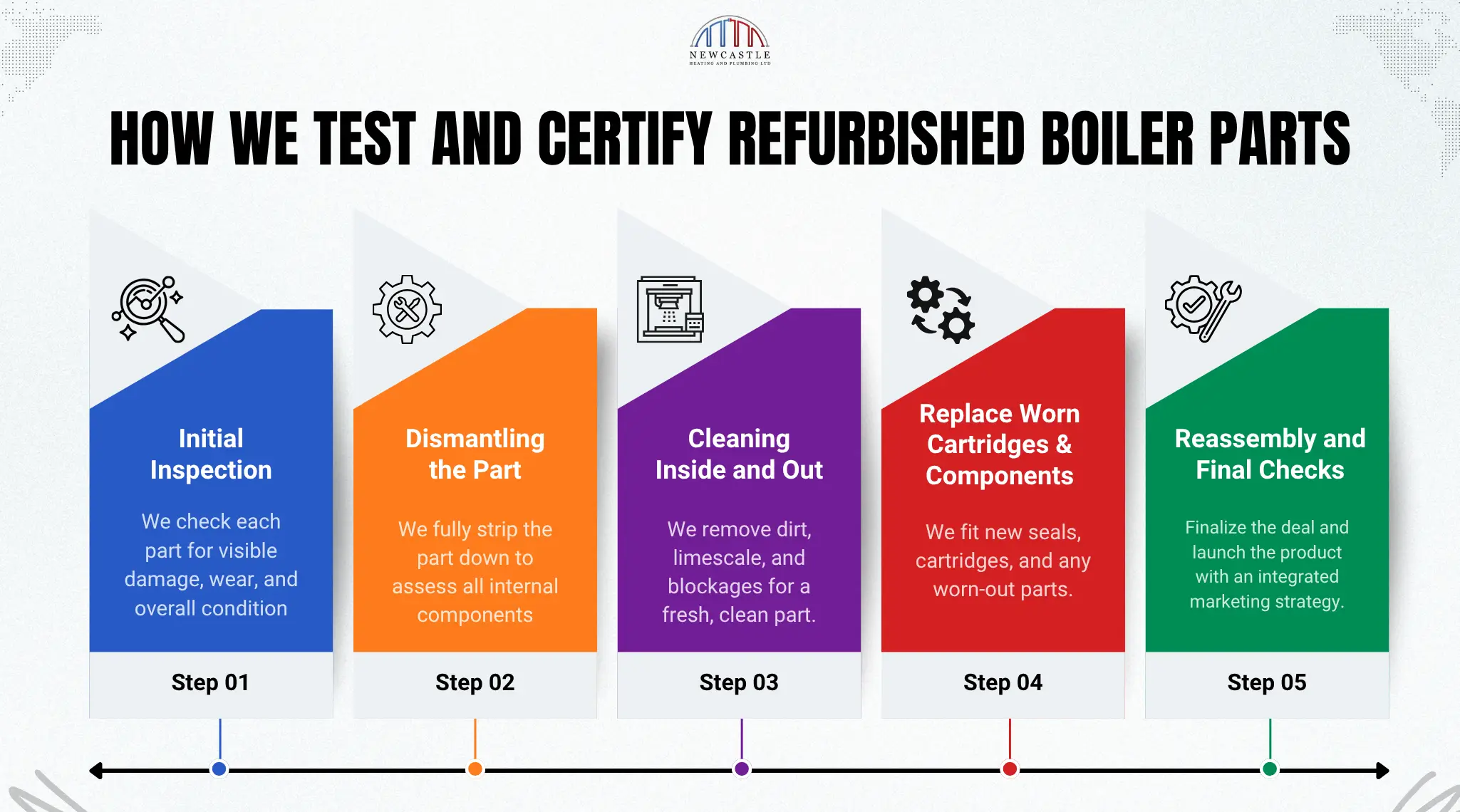

How We Test and Certify Refurbished Boiler Parts

When you buy a refurbished boiler part, you want to know it works just as well as a new one. At Newcastle Heating & Plumbing, we don’t take chances when it comes to quality. Every part we refurbish goes through a hands-on inspection and testing process before we ever send it out.

We don’t just clean the outside and hope for the best. We fully dismantle, inspect, clean, repair, and restore each part to make sure it’s ready to work again – properly and safely.

Here’s how we do it.

Table of contents

Step 1: Initial Inspection

The moment we remove a part from an old boiler, our team gives it a full visual inspection. We look for:

- Signs of wear, rust, or damage

- Faulty seals or weak pressure points

- Cracks, chips, or loose connections

If it doesn’t meet our base standards, we don’t refurbish it. Only parts with solid structure move to the next stage.

Step 2: Dismantling the Part

Next, we dismantle the part completely. This is where the real work begins.

We separate all the components, remove old seals and fittings, and prepare it for deep cleaning. This helps us spot hidden issues you can’t see from the outside

Step 3: Cleaning Inside and Out

Each part is thoroughly cleaned – both internally and externally.

- We remove built-up limescale, rust, and blockages

- We scrub or soak components based on the part type

- We clean tight flow paths, threads, seals, and housing

A clean part is a reliable part – and it’s how we make sure it performs properly again.

Step 4: Replace Worn Cartridges and Components

We often replace key internal components like:

- Cartridges

- Washers

- O-rings

- Seals

- Diaphragms

- Bearings

This step is essential. These are the parts that usually fail over time, and replacing them gives the refurbished unit new life.

Step 5: Reassembly and Final Checks

Once the part is cleaned and repaired, we reassemble it and check everything:

- Alignment and fittings

- Threading and pressure points

- Smooth movement and closure

- No signs of leaks or gaps

This ensures the part is not just “fixed” but functionally strong and safe to use.

What Do We Mean by “Certified”?

We don’t claim external certification labels – and we’re transparent about that.

But we do stand by our process:

- We inspect every part by hand

- We test for fit, pressure, and function

- We only sell parts we’d be confident installing ourselves

- And we back it with real customer trust and satisfaction

Final Step: Ready for Dispatch

Once a part passes all checks, it’s added to our active stock and listed for sale. We pack it carefully and ship it to you fast – knowing it’s ready to install and perform.

This is the same process we’ve used to refurbish thousands of parts, serving engineers, landlords, and homeowners all over the UK.

Conclusion

Refurbished boiler parts don’t just happen – they’re carefully rebuilt, checked, and made ready to work. At Newcastle Heating & Plumbing, we take every step to make sure the parts we sell are safe, clean, and reliable.

So if you want to fix your boiler without breaking the bank, and still feel confident about what you’re installing – our refurbished parts have you covered.